Model WSV Wireline Safety Valve

The Model Wireline Safety Valve provides operators with a means to continue production in the event there is a faulty Tubing Retrievable Safety Valve. Used in conjunction with the Model PLO Permanent Lock Out Tool and Model ECT Communication Tool, the WSV reestablishes the well fail-safe capabilities, allowing production to resume while plans for an eventual workover proceed.

The Model WSV Wireline Safety Valves are designed to be paired with a lock mandrel of choice, including the Enecal Lock Mandrel and with the help of a seal extension, the valve may be installed into a safety valve lock profile or safety valve landing nipple. The selection of Lock Mandrel used with the WSV will be determined by the lock profile of the corresponding Landing Nipple, thus allowing operators the flexibility to use the WSV in a variety of well intervention scenario.

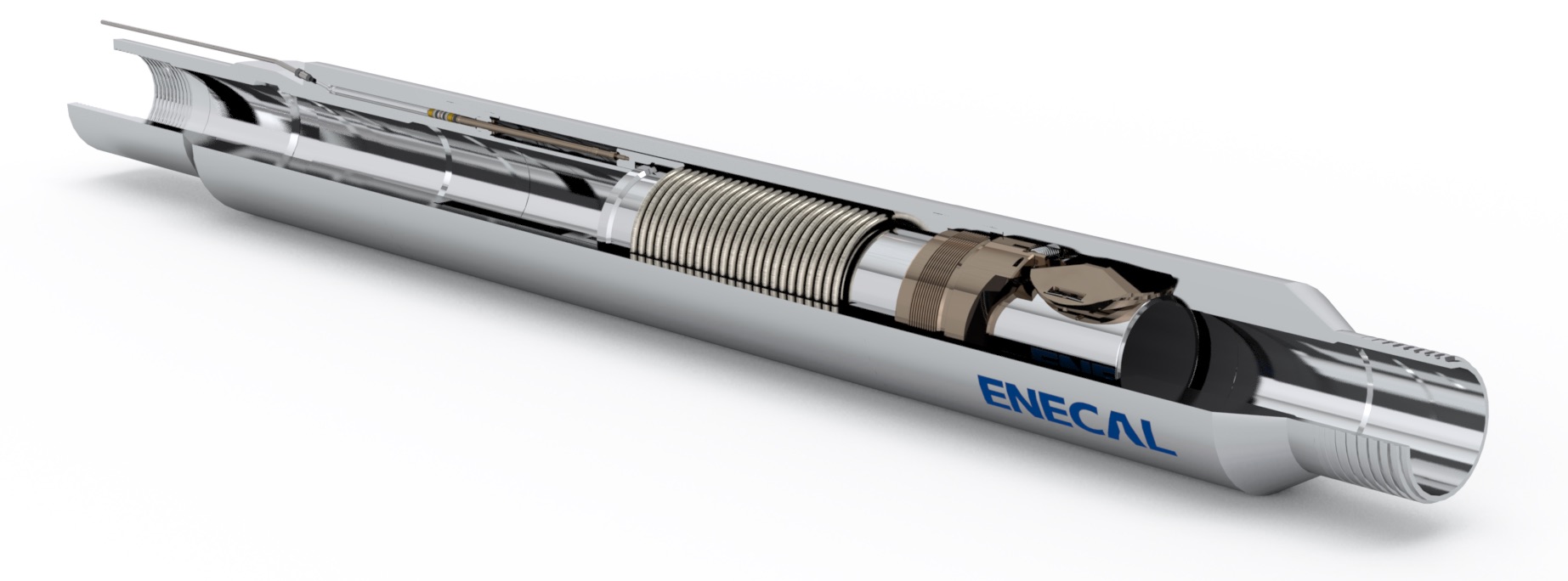

Model WSV Wireline Safety Valves are wireline retrievable, fail-safe subsurface safety valves. When assembled to an appropriate lock, the safety valve is connected by hydraulic control line to the surface emergency shutdown system and held open by hydraulic pressure from the surface. Upon loss of control line pressure, the valve’s large spring forces the flapper closed to shut off the well.

The WSV is designed to endure up to 10,000 psi (68.9 MPa) differential pressures with seal options up to 350°F (177°C) service temperature. Self-equalizing option is available upon request.

Key Features & Benefits:

- Hydraulically Controlled

- Critical components isolated from well environment

- Design simplicity with two moving parts – flow tube and flapper, providing a longer working life

- Rugged construction: unique shaped flapper with high-strength alloy pin eliminates the most common mechanical failures in a flapper valve, bent hinge pins and seat damage

- Positive Sealing: non-elastomeric seal working in conjunction with metal-to-metal seal assures both a high and low pressure seal

- Straight through flow path to allow maximum production rate with minimal restriction

- Emergency kill features: kill fluids can be pumped down the tubing through the closed valve if hydraulic control of the valve is lost and it becomes necessary to kill the well.