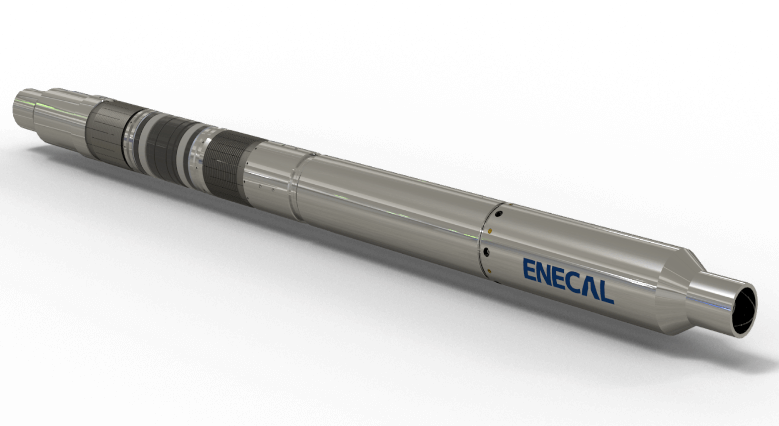

Model PHT Permanent Hydraulic Set Packer

The Model PHT Permanent Hydraulic Set Packer offers exceptional durability and reliability, making it an ideal choice for challenging HP/HT well conditions. Its robust construction ensures longevity and consistent performance, even in the most demanding environments. The packer is engineered to provide a secure seal and anchoring, minimizing the risk of leaks and enhancing well integrity.

Additionally, the PHT Packer is designed with user-friendly installation and operation in mind, allowing for efficient deployment and setting. Its advanced hydraulic setting mechanism simplifies the process, reducing downtime and enhancing operational efficiency. The adaptability of the dual piston configuration offers flexibility to meet various operational requirements, ensuring seamless integration into existing systems.

With its comprehensive sealing capabilities and high-pressure tolerance, the PHT Packer is a vital completion tool for ensuring optimal well performance and safety. Its innovative design and superior materials make it a preferred choice for operators seeking reliable solutions in high-pressure, high-temperature applications.

The PHT Packer employs a multi-duro, multi-material sealing element stack, allowing it to withstand differential pressures up to 15,000 psi (103.4 MPa) in certain sizes, with element options suitable for service temperatures reaching up to 450°F (232°C).

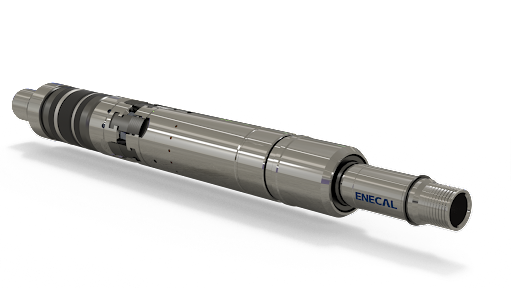

Key Features & Benefits:

- Top of range, high performance packer designed for HPHT applications

- Designed and manufactured to conform to API 11D1 specifications

- Superior multi-durometer, multi-material element package protected from extrusion by expandable metal back-up rings for higher performance

- 360° hardened, bi-directional slips maintain a reliable anchor to casing at high pressure differentials and applied loads

- Double cone option available to maximize anchoring force and casing anchoring footprint

- Double piston option to increase setting load or reduce setting pressure depending on specific well planning

- No mandrel movement during and after setting

- Packer may be field adjusted to achieve desired start-to-set pressure

- Components, including core of slips, retains metallic structure for easy milling

- All components rotationally and axially locked to prevent pre-set of packer when running in well