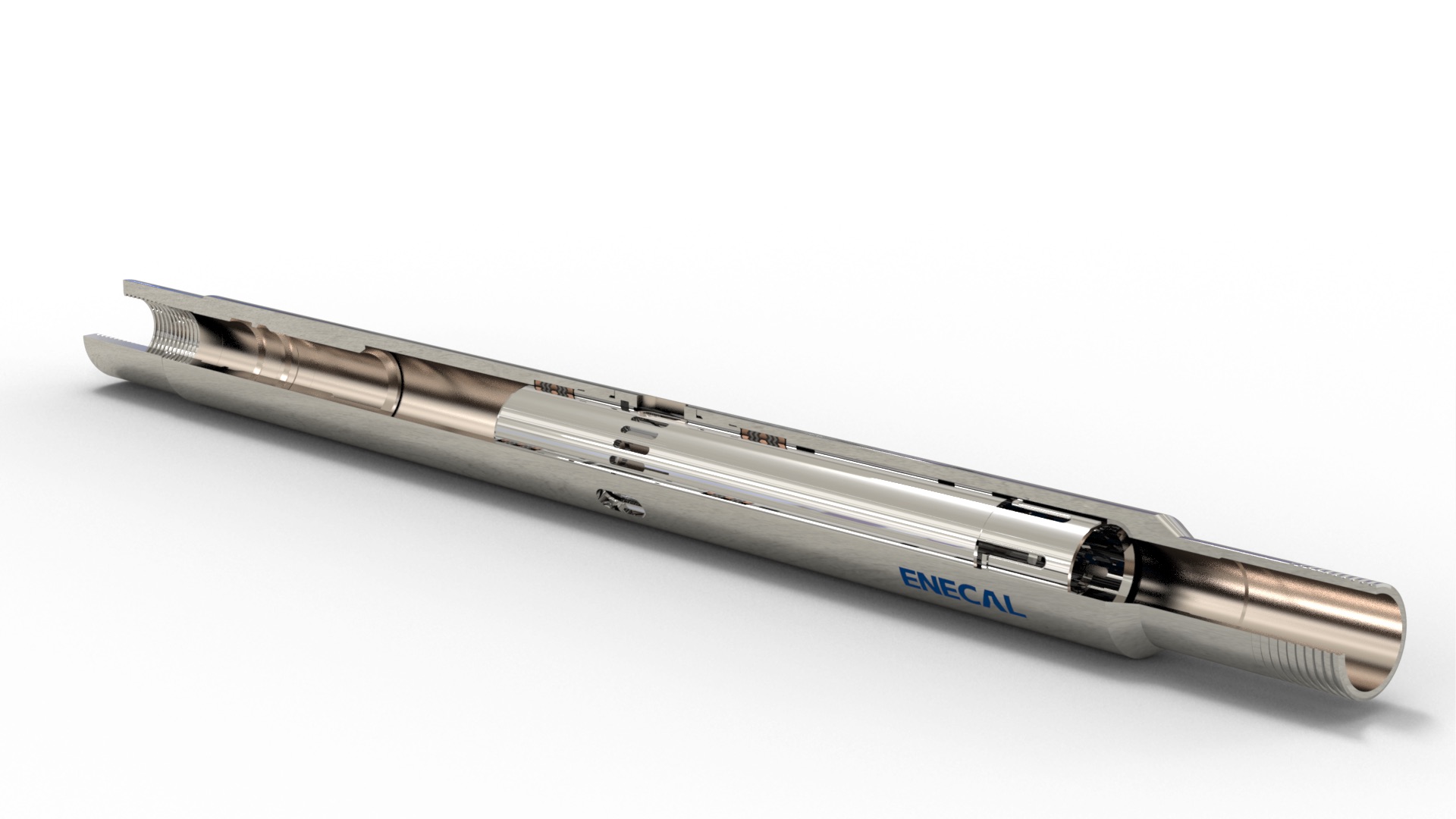

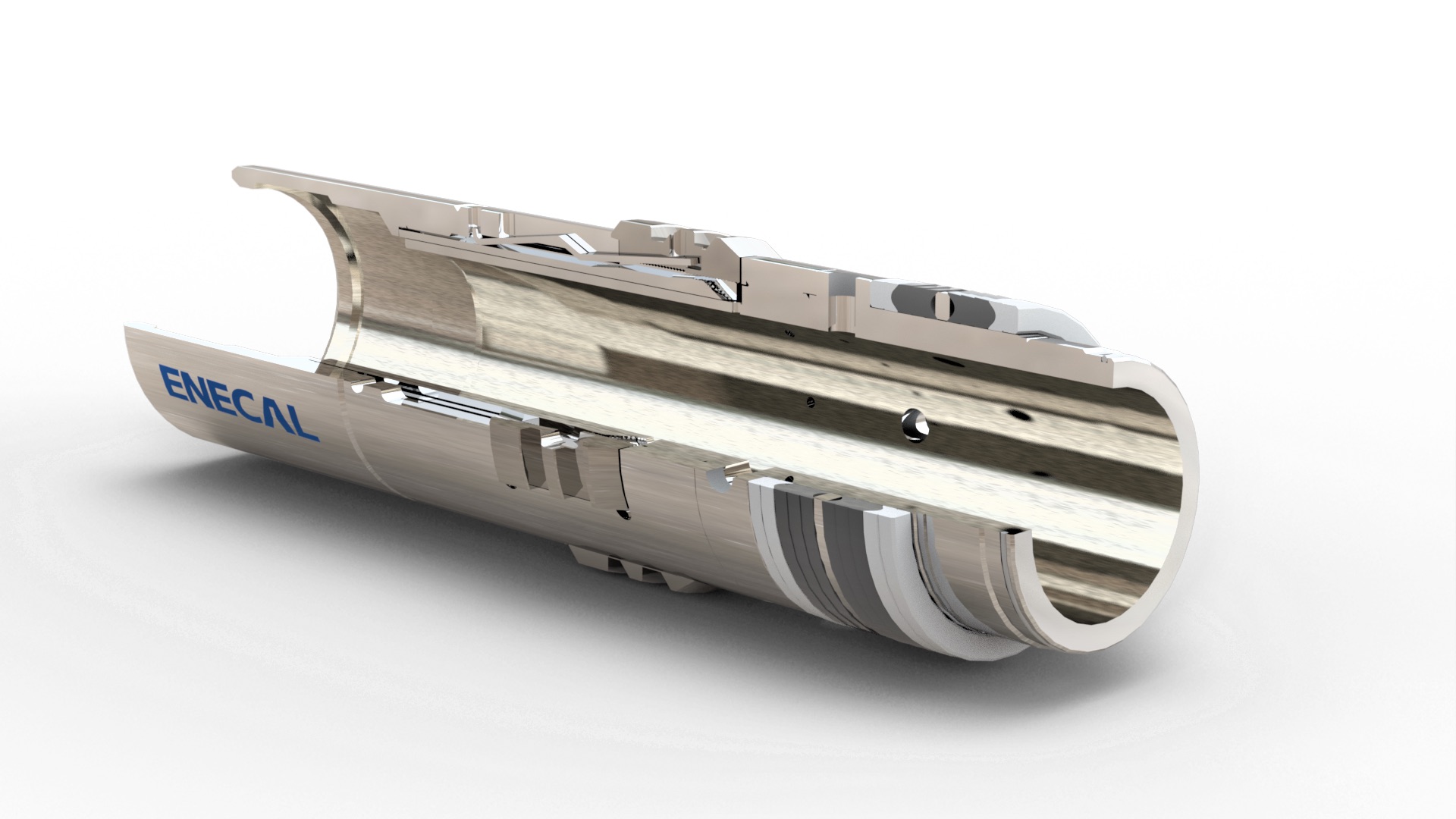

Model SSD Sliding Sleeve

The Model SSD Sliding Sleeve with equalizing, shift-down to open model allows circulation or selective zone production or injection communication between the annulus and tubing. The sleeve is shifted open or closed using standard wireline single or selective shifting tools. Incorporated is a locking profile of any type with compatible size seal bores located above and below the inner sleeve to accommodate wireline tools and accessories.

The nominal working specifications for the sliding sleeve is 10,000 psi (69.0 MPa) rated for a 325°F (163°C) service temperature depending on materials.

Key Features & Benefits:

- Top and bottom sub inner threaded connections are located inside of the seal units eliminating the need to have thread seals or o-ring connections

- Inner sleeve has equalization ports for the ease of opening the sliding sleeve while exposed to tubing and annular differential pressures

- A seal unit protection ring is incorporated between the upper seal unit and milled slots to protect the seals from the rush of passing fluid during sleeve opening. This protection ring allows for slow equalization at high differential pressures

- Seal units are designed with chemically inert non-elastomeric thermoplastic materials to withstand high temperatures and harsh well environments

- Mill slots are used on the inner sleeve and outer connector sub to provide high flow areas and prevent high rate flow erosion. Milled slots also maintain a high tensile strength through the sliding sleeve